Investment Casting - Advanced Techniques and Applications

Medi Study Go

Related Resources

- Comprehensive Guide to Casting Investment and Procedures

- Mastering the Lost Wax Casting Process

- Materials Science in Investment Casting

- Preventing and Correcting Casting Defects

- Casting Procedures - Best Practices and Standards

Introduction to Advanced Investment Casting

Investment casting represents the pinnacle of precision metal casting processes in healthcare applications. This technique, refined over thousands of years yet continuously evolving, delivers the exceptional accuracy required for medical and dental devices. For students preparing for NEET MDS examinations or professionals seeking to deepen their understanding, mastering advanced investment casting techniques provides a significant advantage.

Precision-Focused Equipment for Investment Casting

Advanced Furnaces

Modern investment casting processes rely on precisely controlled furnaces:

- Programmable Burnout Furnaces: These units offer multi-stage temperature programs, essential for complex dental and medical castings. The controlled heating rates prevent investment cracking and ensure complete wax elimination—topics frequently covered in NEET preparation books.

- Induction Melting Systems: These systems provide rapid, controlled heating of casting alloys without contamination, critical for biomedical applications.

- Atmosphere-Controlled Chambers: For reactive metals like titanium, specialized casting equipment maintains protective atmospheres to prevent contamination.

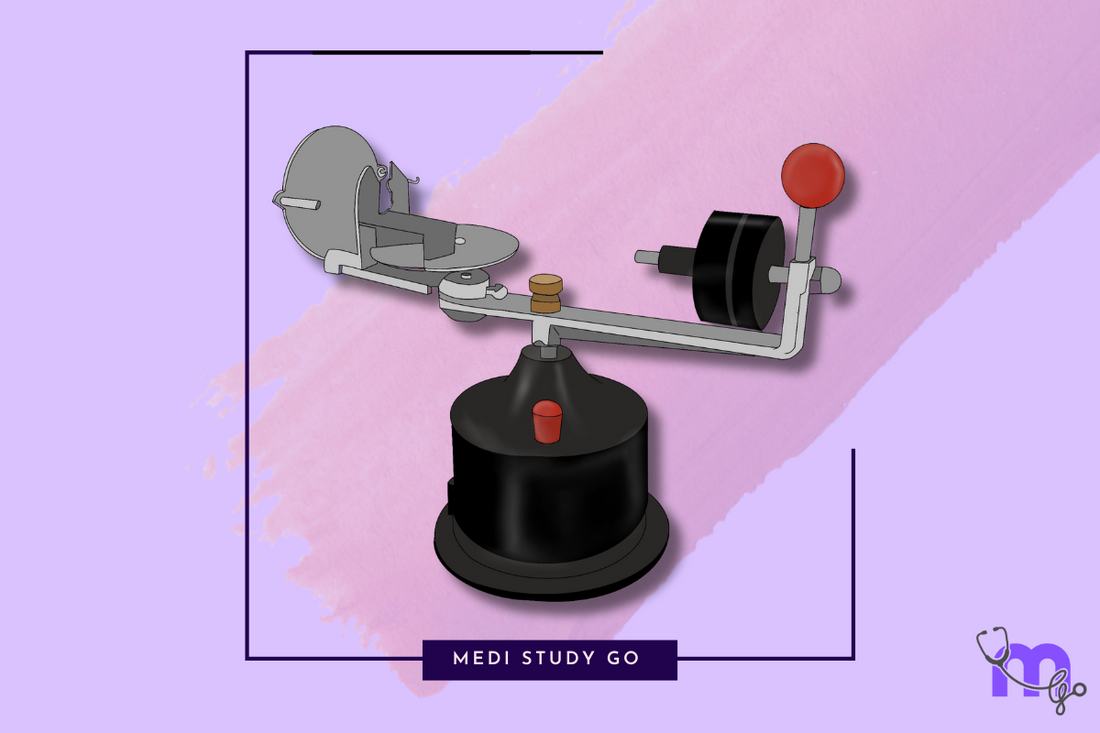

Precision Casting Machines

Several casting machine technologies offer specific advantages:

-

Advanced Centrifugal Casting: Modern centrifugal casting machines feature:

- Digital speed control

- Programmable casting cycles

- Safety interlocks

-

Vacuum-Pressure Casting Systems: These hybrid systems:

- Create initial vacuum to remove gases

- Apply positive pressure during casting

- Reduce porosity in final castings

-

Continuous Casting Equipment: For higher volume medical components:

- Automates multiple castings

- Maintains consistent quality

- Reduces per-unit costs

Understanding these equipment options provides context for NEET exam tips related to dental materials and techniques.

Specialized Investment Materials

Phosphate-Bonded Investments

These investments offer superior properties for advanced applications:

- Higher thermal stability

- Better surface reproduction

- Compatibility with a wider range of alloys

For students using flashcard applications for NEET, understanding the chemistry behind these materials provides deeper knowledge than simple memorization.

Computer-Optimized Expansion Control

Modern investments feature precisely engineered expansion characteristics:

- Controlled hygroscopic expansion

- Predictable thermal expansion

- Compensation settings for different alloys

These properties ensure that final castings fit perfectly—essential knowledge for NEET previous year question paper preparation.

Specialty Investment Formulations

Advanced applications may require specialized investment materials:

- Ultra-Fine Grain: For capturing microscopic details

- High-Temperature: For casting titanium and other reactive metals

- Rapid-Set: For accelerated production workflows

Advanced Pattern Creation Techniques

Digital Pattern Production

Modern pattern creation has evolved beyond traditional wax carving:

-

CAD/CAM Wax Milling: Computer-controlled milling of wax blanks offers:

- Precise dimensions

- Consistent results

- Complex geometries

-

3D Printed Patterns: Additive manufacturing creates patterns using:

- Photopolymer resins

- Castable waxes

- Hybrid materials

-

Digital Design Software: Specialized software enables:

- Virtual articulation

- Stress analysis

- Automated design features

These digital workflows increasingly appear in NEET PYQ as technology transforms dental practice.

Advanced Spruing Techniques

Sophisticated spruing approaches prevent common defects:

- Reservoir Design: Strategic placement and sizing of reservoirs compensates for solidification shrinkage

- Multiple Sprue Systems: Complex geometries may require multiple entry points

- Computer-Simulated Metal Flow: Software can predict optimal sprue placement

Understanding these advanced techniques helps in answering application-based questions in NEET mock tests.Industry Applications of Investment Casting

Dental Applications

The dental field represents a primary application for precision casting:

-

Fixed Prosthodontics:

- Single crowns

- Multi-unit bridges

- Custom abutments

- Implant components

-

Removable Prosthodontics:

- Partial denture frameworks

- Precision attachments

- Implant bars

-

Orthodontics:

- Custom appliance components

- Expansion devices

These applications form core content in NEET books and examination syllabi.

Medical Device Manufacturing

Investment casting plays a crucial role in medical device production:

-

Orthopedic Implants:

- Joint replacement components

- Bone plates and screws

- Custom reconstructive implants

-

Surgical Instruments:

- Precision forceps and clamps

- Endoscopic instrument components

- Microsurgical tools

-

Specialized Medical Equipment:

- Imaging device components

- Radiation therapy equipment parts

- Laboratory instrument precision parts

Understanding these applications provides context for students using revision tools for NEET to connect theoretical knowledge with practical applications.

Case Studies in Healthcare Applications

Case Study 1: Custom Cranial Implant

A patient required a custom cranial implant following trauma. The process involved:

- CT scan data conversion to 3D model

- Digital design of custom implant

- 3D printing of pattern

- Investment casting in biocompatible titanium alloy

- Surface finishing and sterilization

This example demonstrates how custom investment casting services support personalized medicine.

Case Study 2: Precision Dental Bridge Framework

A complex dental restoration required exceptional fit and biocompatibility:

- Digital impression of prepared teeth

- Computer design of framework

- 3D printing of pattern

- Investment casting in noble metal alloy

- Porcelain application and finishing

Such cases illustrate why investment casting remains relevant despite newer technologies.

Future Trends in Investment Casting

Hybrid Manufacturing Approaches

Emerging technologies combine traditional casting with advanced techniques:

- Cast components with 3D printed features

- Selective surface treatments

- Composite material integration

These innovations represent likely topics for future NEET MDS examinations.

Bioactive Material Integration

Research focuses on enhancing biological performance:

- Casting porous structures for tissue integration

- Incorporating bioactive elements

- Gradient structures with varying properties

Automation and AI Integration

Manufacturing intelligence is transforming casting:

- AI-optimized sprue designs

- Robotics for labor-intensive steps

- Predictive quality control systems

For students using flashcard technique for study, staying current with these emerging trends distinguishes outstanding exam performance.

Conclusion

Advanced investment casting techniques continue to evolve, combining ancient wisdom with cutting-edge technology. For healthcare professionals and students preparing for NEET exams, understanding these specialized approaches provides both practical knowledge and examination advantages.

As precision metal casting manufacturers continue to innovate, the possibilities for improved medical and dental devices expand. Whether you're a dental student mastering the fundamentals or a practicing clinician seeking to understand your laboratory partners' capabilities, investment casting knowledge remains essential in modern healthcare.