Casting Procedures: Best Practices and Standards

Medi Study Go

Related Resources

- Comprehensive Guide to Casting Investment and Procedures

- Investment Casting - Advanced Techniques and Applications

- Mastering the Lost Wax Casting Process

- Materials Science in Investment Casting

- Preventing and Correcting Casting Defects

Introduction

Proper casting procedures are essential for producing high-quality metal components. This document outlines industry best practices and standards to ensure consistent quality, safety, and efficiency in metal casting operations.

Pre-Casting Preparations

Material Selection and Preparation

- Verify material composition and quality before use

- Store raw materials in dry, controlled environments

- Properly label all materials with composition and batch information

- Perform material testing as required by relevant standards

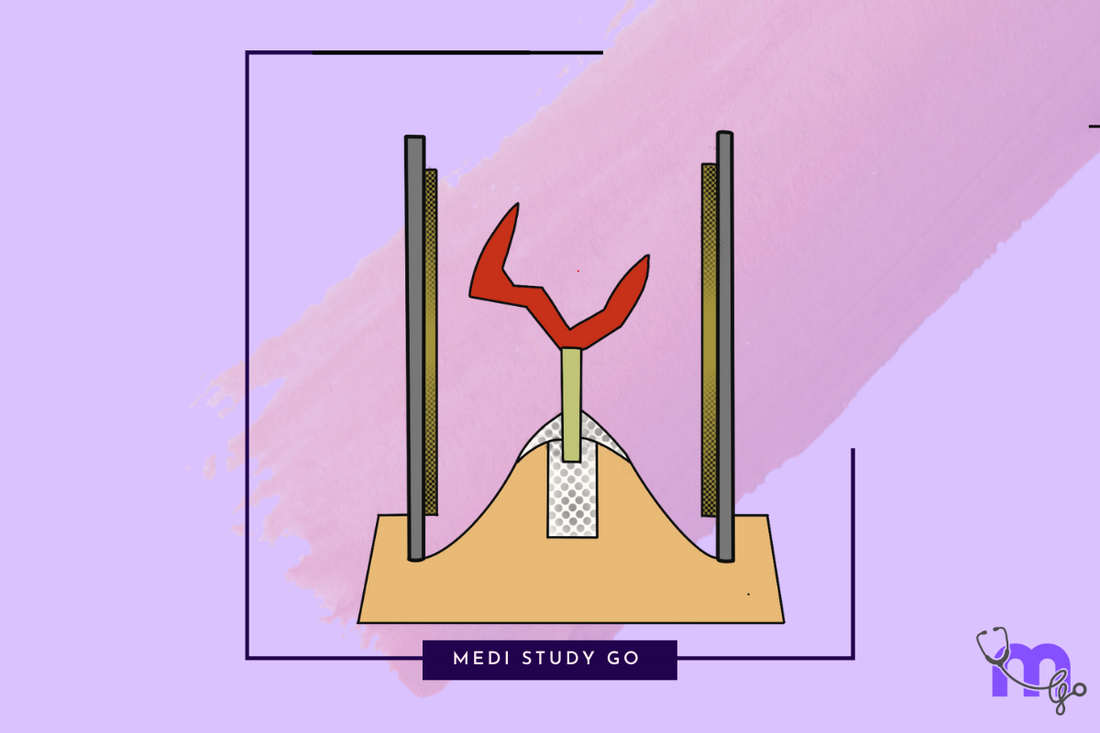

Pattern and Mold Preparation

- Inspect patterns for damage before each use

- Apply release agents evenly and in appropriate quantities

- Ensure proper venting in all molds

- Verify mold cavity dimensions against specifications

- Pre-heat molds when required by procedure

Equipment Readiness

- Perform required equipment inspections before beginning casting operations

- Verify temperature control systems are calibrated and operational

- Ensure all safety equipment is functional and accessible

- Document equipment checks in daily logs

Melting Procedures

Temperature Control

- Monitor and document metal temperatures throughout the melting process

- Use calibrated thermocouples and pyrometers

- Follow specified temperature ranges for each alloy

- Implement temperature alarms for out-of-range conditions

Alloying and Treatment

- Add alloying elements according to specified procedures and proportions

- Perform degassing operations as required

- Document all additions and treatments with timestamps

- Take samples for composition analysis at specified intervals

Contamination Prevention

- Use dedicated tools for different alloys to prevent cross-contamination

- Clean furnace and transfer equipment between different alloy runs

- Implement procedures to prevent slag inclusion

- Filter molten metal as specified by product requirements

Pouring Operations

Pouring Technique

- Maintain consistent pouring temperature for each alloy type

- Use appropriate pouring rate to minimize turbulence

- Ensure continuous pouring when required

- Position ladles correctly to minimize splash and oxidation

Timing Considerations

- Document pour start and end times

- Adhere to maximum holding time specifications for molten metal

- Coordinate pouring operations to minimize idle time

- Follow specified cooling rates when applicable

Documentation

- Record pouring parameters for each batch

- Document any process deviations

- Maintain traceability between poured components and material batches

- Capture environmental conditions during pouring

Solidification and Cooling

Controlled Cooling

- Follow specified cooling profiles for each alloy and part geometry

- Use cooling fixtures as required by procedure

- Monitor and document cooling rates

- Protect cooling castings from drafts and environmental fluctuations

Stress Management

- Implement procedures to minimize residual stresses

- Follow proper knockout timing to prevent thermal shock

- Allow adequate time for complete solidification before handling

- Use controlled cooling for stress-sensitive components

Post-Casting Operations

Inspection Procedures

- Perform visual inspections on all castings

- Implement appropriate non-destructive testing methods

- Document all inspection results

- Segregate non-conforming parts

Cleaning and Finishing

- Follow specified cleaning procedures

- Use appropriate blast media for each alloy type

- Implement dust collection and ventilation

- Perform finishing operations according to product specifications

Heat Treatment

- Follow specified heat treatment cycles

- Document temperature profiles during heat treatment

- Verify heat treatment results through hardness testing

- Maintain traceability between heat treatment batches and casting lots

Quality Control

Sampling and Testing

- Follow sampling plans based on batch size and criticality

- Perform mechanical testing according to applicable standards

- Maintain calibration of all testing equipment

- Document and analyze test results

Process Control

- Monitor key process parameters

- Implement statistical process control where applicable

- Conduct regular process capability studies

- Address process drift before it affects quality

Documentation and Traceability

- Maintain complete process documentation

- Ensure traceability from raw material to finished product

- Archive quality records according to industry requirements

- Document all process deviations and corrective actions

Safety Standards

Personal Protective Equipment

- Require appropriate PPE for each operation

- Inspect PPE regularly for damage or wear

- Train personnel on proper PPE use

- Maintain PPE inventory and replacement schedule

Emergency Procedures

- Implement and practice emergency response procedures

- Maintain emergency equipment in ready condition

- Post clear evacuation routes and emergency contact information

- Train all personnel on metal-specific emergency responses

Environmental Controls

- Implement fume extraction systems

- Monitor air quality in casting areas

- Properly dispose of hazardous waste

- Follow applicable environmental regulations

Continuous Improvement

Process Audits

- Conduct regular internal audits of casting procedures

- Document audit findings and corrective actions

- Track implementation of improvements

- Benchmark against industry standards

Training and Competency

- Implement comprehensive training programs

- Verify competency through practical demonstrations

- Document training records

- Provide refresher training at appropriate intervals

Feedback Mechanisms

- Establish channels for operator feedback

- Review customer complaints and returns

- Analyze scrap and rework data

- Implement lessons learned from previous issues

Investment Mixing and Application Excellence

Application Standards

- Complete investment coverage without air entrapment

- Proper ring liner preparation and placement

- Appropriate bench set time before burnout

- Detailed documentation of mixing ratios and conditions

Burnout and Casting Excellence

Burnout Procedures

Optimal burnout protocols include:

Temperature Cycling

- Programmed heating rates appropriate to investment type

- Specific hold temperatures and durations

- Controlled cooling rates when applicable

- Verification of complete wax elimination

Furnace Management

- Regular calibration of temperature controllers

- Even heat distribution verification

- Proper positioning of rings in furnace

- Maintenance of heating elements

- Contamination prevention between burnout cycles

These burnout parameters directly impact casting success—knowledge crucial for NEET examination preparation and clinical practice.

Casting Execution

Excellence in casting requires:

Equipment Readiness

- Proper crucible selection and preparation

- Torch or induction unit calibration

- Centrifugal or vacuum pressure casting machine maintenance

- Verification of all safety systems

Material Handling

- Proper alloy selection for application

- Virgin versus reclaimed metal ratios

- Flux application when appropriate

- Proper melting technique

- Recognition of optimal casting temperature

Casting Technique

- Proper ring temperature at casting

- Optimal timing from melt to cast

- Appropriate force application

- Complete filling verification

- Controlled cooling protocols

Post-Casting Procedures

Divesting and Cleaning

Optimal protocols include:

Divesting Methods

- Appropriate cooling time before divesting

- Proper divesting technique to prevent damage

- Gradual investment removal methods

- Protection of delicate structures

- Complete removal of investment materials

Surface Preparation

- Appropriate abrasive selection

- Directional finishing technique

- Prevention of overheating during finishing

- Preservation of detail and margins

- Contamination prevention between processing steps

Quality Verification

Excellence in verification includes:

Visual Inspection

- Systematic examination protocol

- Appropriate magnification

- Proper lighting conditions

- Documentation of findings

Dimensional Accuracy

- Fit verification methods

- Margin adaptation assessment

- Internal adaptation evaluation

- Occlusal relationship verification

Surface Quality

- Smoothness standards

- Porosity examination

- Inclusion detection

- Surface finish requirements

These verification steps ensure casting quality—knowledge tested in NEET practical examinations and essential in clinical practice.

Documentation and Traceability

Material Traceability

Best practices include:

- Batch recording of all materials

- Expiration date verification

- Manufacturer certification documentation

- Material safety data sheet maintenance

- Lot number tracking through production

Process Documentation

Excellence requires:

- Detailed procedure logs

- Specific parameter recording

- Operator identification

- Equipment identification

- Date and time stamping

- Exception documentation

- Corrective action records

Quality Records

Comprehensive records include:

- Final inspection results

- Acceptance criteria verification

- Non-conformance documentation

- Corrective actions taken

- Preventive measures implemented

- Quality trending analysis

These documentation practices support quality assurance—knowledge valuable for NEET test series preparation and professional practice.

Training and Competency Standards

Education Requirements

Excellence in casting requires:

- Foundational materials science knowledge

- Understanding of metallurgical principles

- Comprehensive procedural training

- Regular continuing education

- Current knowledge of standards and regulations

Skill Verification

Best practices include:

- Competency demonstration requirements

- Regular skill assessment

- Error rate monitoring

- Coaching and mentoring programs

- Advanced certification opportunities

Continuous Improvement

Excellence demands:

- Regular review of current literature

- Implementation of evidence-based techniques

- Participation in quality circles

- Problem-solving methodology application

- Process optimization initiatives

These learning standards support professional development—knowledge essential for NEET coaching and lifelong learning.

Specialized Applications in Healthcare

Dental Prosthetics

Specific standards for dental applications include:

- Margin adaptation requirements

- Surface finish specifications

- Biocompatibility standards

- Wear resistance criteria

- Corrosion resistance requirements

Medical Implants

Excellence in implant casting requires:

- Enhanced cleanliness standards

- Specialized alloy handling

- Stricter porosity limitations

- Comprehensive documentation

- Extended traceability requirements

- More rigorous testing protocols

Custom Instrumentation

Best practices include:

- Enhanced durability requirements

- Special finish considerations

- Ergonomic design integration

- Sterilization compatibility

Understanding these specialized applications provides context for NEET MDS aspirants and professionals in various healthcare sectors.

Troubleshooting Common Issues

Defect Identification

Excellence requires:

- Systematic evaluation methodology

- Root cause analysis capability

- Documentation of findings

- Correlation to process variables

Correction Strategies

Best practices include:

- Procedural modification protocols

- Material substitution guidelines

- Equipment adjustment parameters

- Environment modification approaches

Prevention Planning

Excellence demands:

- Preventive action implementation

- Process control enhancement

- Training updates

- Equipment maintenance scheduling

- Material quality verification

These troubleshooting approaches ensure continuous quality—knowledge tested in NEET question papers and essential in professional practice.

Conclusion

Mastering casting procedures requires dedication to established standards and best practices. For healthcare professionals and NEET MDS aspirants, this knowledge forms the foundation of exceptional clinical outcomes. By implementing these guidelines, practitioners ensure consistent quality, patient satisfaction, and professional excellence.

The investment casting process, when executed with precision and attention to detail, produces results that enhance patient care and professional reputation. Continuous learning and commitment to quality remain the hallmarks of excellence in this essential aspect of healthcare delivery.